- Description

- Additional information

- TYPES OF FLUX

Description

Sn50 Pb50 according to the UNE-EN-ISO 9453 standard. Alloy 111.

Ideal alloy for repairing lead pipes as well as soldering lead, zinc and copper plates, in general for soldering that requires a filler material with a low melting point. Melting range: 183 – 215 ºC. Diameters: This product may be supplied in diameters from 0.5 mm Ø (in this diameter reels only 100g, 250g and 500g…) to Ø 6 mm. Formats: Supplied in plastic reels 100 gr.: 30 units / box; 250 gr.: 50 units / box; 500 gr.: 20 units / box; 1 Kg.: 10 units / box; 2 Kg. and 4 Kg. on request.

Additional information

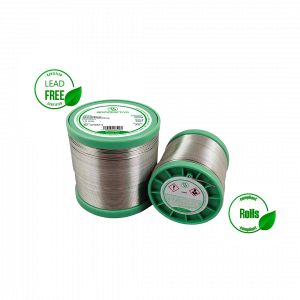

| Application | Soldering, Electronic, Hand & Robotic Soldering, Re-work |

|---|---|

| Composition | Sn60 Pb40 |

| Flux Content | YES |

| Lead Free | NO |

| Flux name | Classification and regulation |

| B0.1 | 1.1.2.B (EN ISO 29454-1) / ROL1 (J-STD-004) EN 61190 1-3:2007 |

| B0.2 | 1.1.3.B (EN ISO 29454-1) / ROLO (J-STD-004) EN 61190 1-3:2007 |

| B1.1 | 1.2.2.B (EN ISO 29454-1) / REM1 (J-STD-004) EN 61190 1-3:2007 |

| B1.2 | 1.2.3.B (EN ISO 29454-1) / REM0 (J-STD-004) EN 61190 1-3:2007 |

| B2.1 | 1.1.2.B (EN ISO 29454-1) / ROM1 (J-STD-004) EN 61190 1-3:2007 |

| B2.2 | 1.1.3.B (EN ISO 29454-1) / ROMO (J-STD-004) EN 61190 1-3:2007 |

| B3.1 | 2.1.3.B (EN ISO 29454-1) / ORM1 (J-STD-004) EN 61190 1-3:2007 |

| B3.2 | 3.1.1.B (EN ISO 29454-1) / INM1 (J-STD-004) EN 61190 1-3:2007 |

| B4.1 | 1.2.2.B (EN ISO 29454-1) / REL1 (J-STD-004) EN 61190 1-3:2007 |

| B4.2 | 1.2.3.B (EN ISO 29454-1) / REL0 (J-STD-004) EN 61190 1-3:2007 |